Solid Wire,Welding Electrode,Flux Cored Wire

Flux Cored Electrodes For Arc Welding.

This flux cored electrodes is a titanium oxide type CO2 gas shielded flux cored wire with excellent welding performance,soft and stable arc,small spatter,easy slag removal and beautiful weld formation.

It is suitable for flat welding and transverse welding,it can be used for all position welding with high welding efficiency.

The weld metal has been toughened by trace elements,it has excellent low temperature toughness, good crack resistance and stable internal quality.

It is used for welding of structural parts of carbon steel and low alloy structural steel with tensile strength ≥ 490mpa, and is most widely used for welding of important structures such as shipbuilding,machinery manufacturing,pressure vessel,boiler, petroleum machinery,chemical machinery,lifting machinery,etc.

For the single-pass and multi-pass welding of grade Rm 500MPa level’s steel.

Better welding performance and good gas pore resistance.

1.The rust,oil,water and other impurities of the weld area must be removed before welding

2.The mechanical properties of all weld metal be decided by heat input,normally the small heat input will better than larger one

Characteristics:

This GMAW wire is for Rm 500MPa level carbon steel with shield gas of CO2 or M21.

Small spatter,beautiful appearance,high deposition efficiency and small weld metal porosity sensibility.

All positions is suitable.

Ref.THQ-50C/2014-01

Specification:ER50-6

Diameter:0.8/1.0/1.2/1.6(mm)

ISO 14341-A-G42 3C1 Z3Si1

Shielding Gas EN ISO14175:C1

Current Polarity:DCEP

Positions:PA,PB,PC,PD,PE,PF,PG

CE

0036

07

0036-CPR-S073

EN 13479+ISO 14341

Use in metallic structures or in composite metal and concrete structures

Compliance with:

GB/T8110-2008 ER50-6

ISO 14341-A-G42 3C1 Z3Si1

AWS A5.18 ER70S-6

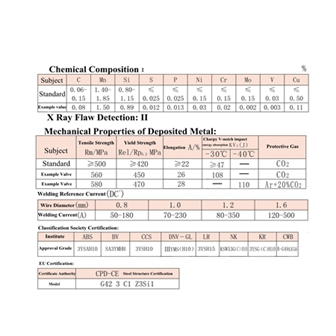

EU Certification:

Certification Authoirty:CPD-CE certification of steel structure

Grade:ISO14341-A-G42 3C1 Z3Si1

Chemical Composition of Wire:

C:0.06-0.15,result 0.08

Mn:1.40-1.85,result 1.50

Si:0.80-1.15,result 0.89

S:Less than or equal to 0.025,result 0.012

P:Less than or equal to 0.025,result 0.013

Ni:Less than or equal to 0.15,result 0.03

Cr:Less than or equal to 0.15,result 0.02

Mo:Less than or equal to 0.15,result 0.002

V:Less than or equal to 0.03,result 0.003

Cu:Less than or equal to 0.50,result 0.11

Mechanical Properties of All Weld Metal:(CO2)

Rm/MPa:More than or equal to 500,result 540

Rel/Rp0.2/MPa:More than or equal to 420,result 450

A/%:More than or equal to 22,result 26

KV2(-30C)/J:More than or equal to 27,result 100

X-ray Radiographic Inspection:Level II

Typical Operating Procedures:(DC+)

Diameter(0.8mm):50-180

Diameter(1.0mm):70-230

Diameter(1.2mm):80-350

Diameter(1.6mm):120-500

Classification of Society Certification:

Ship Inspection Agency:ABS

Level of Recognition:3YSAH10

Ship Inspection Agency:LR

Level of Recognition:3YSAH15

Ship Inspection Agency:BV

Level of Recognition:SA3YMHH

Ship Inspection Agency:NK

Level of Recognition:KSW53G(C)H10

Ship Inspection Agency:CCS

Level of Recognition:3YSH10

Ship Inspection Agency:KR

Level of Recognition:3YSG(C)H10

Ship Inspection Agency:DNV.GL

Level of Recognition:IIIYMS(H10)

Ship Inspection Agency:CWB

Level of Recognition:B-G49A3CG6

Dia 1.2mm

Dia 1.4mm

Dia 1.6mm

Model:THY-51B

AWS A5.18 ER70S-6

ISO 14341-A-G42 3C1 ZSSi1