We aim to meet the varied demands of our clients and serve them effectively,with the different gas cylinders.

Cylinder shall be shot blasted to standard st 2.5,then each cylinder will be painted with one coat of primer thickness (50) and one coat final paint thickness (50) color to client choice (silver).

a-ON valve neck must stamp the following information

Name of supplier .

Date month/year .

Serial No.of production .

b.Other information on guard ring or base ring

Hydrostatic test pressure (bar).

Design pressure (bar).

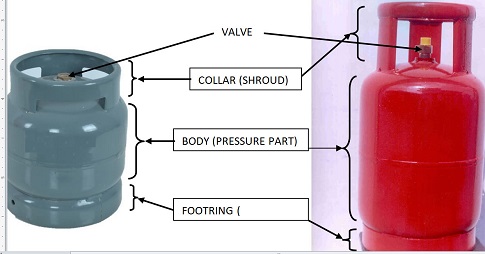

The shape and dimensions of guard ring is according to drawing No. GFC/2011 Plate material according to (ASTM A 569) or (ST 37-2) Din 17100,thickness (2.5mm ). collar to be welded on cylinder body by automatic CO2 welding in four places(5cm) length.

The shape and dimensions of foot ring is according to drawing No.GFC/2011. Plate material according to (ASTM A 569) or (ST 37-2) Din 17100, thickness (3mm)foot Ring to be welded on cylinder body by automatic CO2 welding fully welded from outside.

Valve Boss dimension shall be according to drawing No.GFC/2011.

It shall be manufactured by either

a.Machining from round bar material Or

b.forging from hot finished forgeable and wieldable carbon steel round bar.

Bars shall be fined grained size and shall be processed from arsenic free steel.