DU201 Nondestructive Testing Equipment Weld Inspection X-Ray System

Key Features:

High-Quality X-ray Imaging: Equipped with a 160kV X-ray source, ensuring clear and precise weld inspection.

Longitudinal Weld Inspection: The C-arm design enables the simultaneous movement of the detector and X-ray source along the weld seam.

Circumferential Weld Inspection: The system rotates the cylinder for automatic continuous imaging of circumferential welds.

High Dynamic Range Flat Panel Detector (FPD): Provides excellent image quality.

High Inspection Efficiency: Processes images at 3 to 5 seconds per image.

Low Inspection Cost: Optimized system design reduces operational expenses.

Standards Compliance: Meets the latest GB/T 17925-2009, NB/T 47013.11-2015, and ASME V standards.

AI Weld Defect Recognition (Optional): Enhances inspection efficiency and reduces human error.

Applicable Workpieces:

Inspection Scope: Supports 100% or sample inspection of circumferential and longitudinal welds.

Material Compatibility: Material: Fe, Single Wall Thickness ≤4.0mm.

LPG Cylinder Specifications: Maximum size: 400 mm × 1500 mm, maximum load 60kg.

X-Ray Source

Imaging System

Image Processing and Control Software

The image processing and control software in the DU201 Cylinder Weld Inspection X-Ray System features a modular design, integrating various functions such as imaging inspection, electrical control, motion control, and X-ray machine control into a single interface, while also monitoring the system's operational status.

The software ensures that users can set parameters for speed, distance, synchronization, and more, for optimized inspection efficiency.

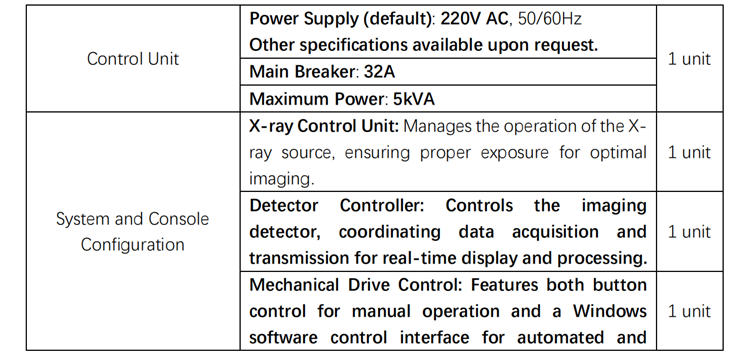

System Console

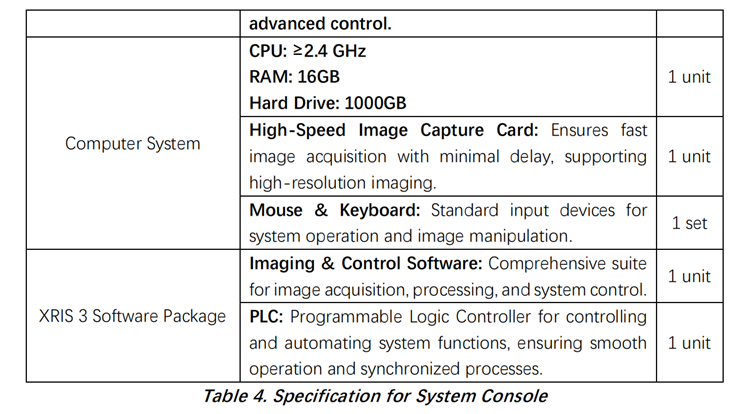

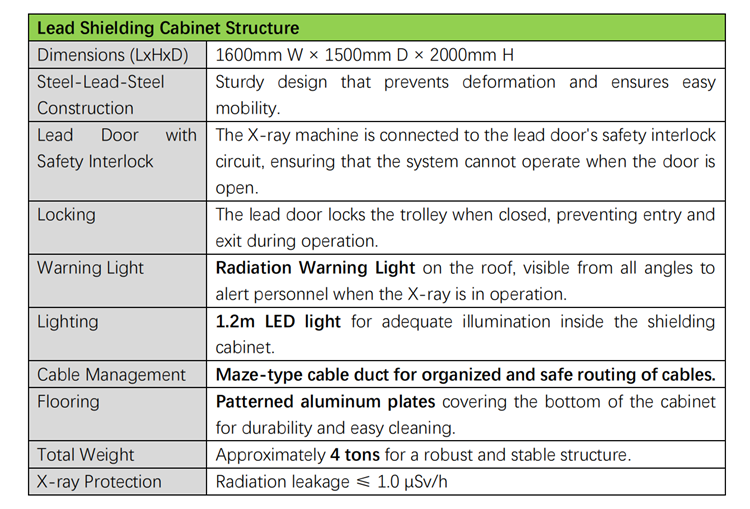

Lead Shielding Cabinet

The Lead Shielding Cabinet provides a safe and secure environment for the DU201 Cylinder Weld Inspection X-Ray System, ensuring proper radiation protection and operational efficiency.

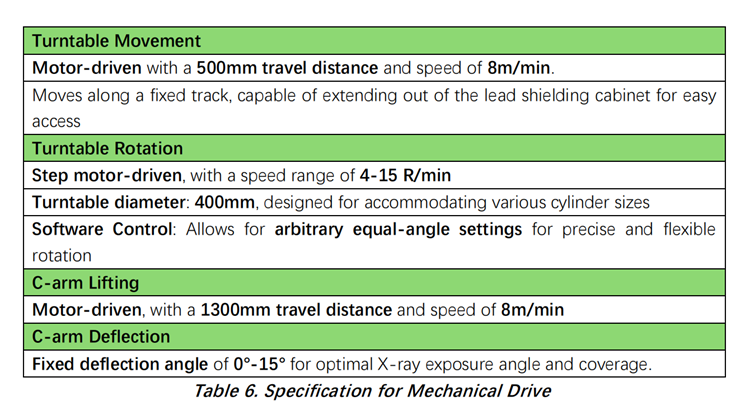

Mechanical Drive

Mechanical Drive

The DU201 Cylinder Weld Inspection X-Ray System includes a set of mechanical drive systems designed for precise movement, efficient operation, and automated inspection.

Key Components

X-Ray Real-Time Imaging Detect System Equipment

Technical Protocol:

DU201 Cylinder Weld Inspection X-ray Machine 100% Inspection, Equipped with Rotational Drive

100% dynamic and static imaging

Synchronized movement of detectors and radiation sources at both ends of the C-arm for longitudinal weld inspection

Cylinder rotation for circumferential weld inspection, equipped with continuous automatic filming function

Extremely low inspection cost

Configured with high dynamic range flat panel detector (FPD)

Inspection efficiency: ~3 seconds per image

Image quality complies with the latest GB/T17925-2009 and NB/T47013.11-2015 standards

Applicable Workpieces:

Inspection objects: 100% inspection or sampling of circumferential and longitudinal welds

Material thickness: ≤6.0mm, Material: Fe

Maximum cylinder dimensions: 400*1500mm

System Composition and Technical Parameters:

The DU201 primarily consists of five components: X-ray source, imager, system console, protective lead room, and mechanical transmission.

X-ray Source – Constant Voltage X-ray Source

Model: DG160MI VJX

Focal Spot Size: 0.45mm

X-ray Power: 480W, High Frequency Control

Radiation Angle: 40°x30°

High Voltage: 30-160kV, Increment 0.1kV, Accuracy ±0.1%

Temperature Drift: 80ppm/°C

Current: 0.2-3mA, Increment 0.1mA, Accuracy ±0.5%

Temperature Drift: 50ppm/°C

Cooling: Recirculating Oil Cooling

Dimensions: 35x40x14cm

Weight: 25kg

2. Imager

Flat Panel Imager: DEETEE, Finland

Effective Area: 130mmx130mm

Scintillator: CsI

Pixel Pitch: 127um

Pixel Count: 1024x1024

Frame Rate: 30fps (1:1)

Interface: Gigabit Ethernet 15m

Fill Factor: 57%

Energy Range: ≤225kV

Temperature: 10~35ºC (Operation), -20~70ºC (Transport)

Humidity: 10~90% (Non-condensing)

Dimensions: 18.3W x 17.6H x 5.7D(cm), Weight: 2.1kg

Power Supply Input: 100-240Vac, 50/60Hz, 15W

3. Image Processing and Control Software

The software system is designed with a modular approach, integrating imaging detection, electrical control, transmission control, and X-ray machine control within the same interface, while monitoring motion status; setting motion speed, distance, synchronization, and other parameters.