Oxygen Cylinder Hydraulic Test Machine and Equipment

Oxygen Cylinder Hydraulic Test Machine and Equipment,Seamless Steel Cylinder Hydraulic Test Equipment.

Applicable to the range of seamless steel cylinders:

1、Diameter 219~425mm;length 650~2000mm

2、Working medium water

3、Designed pressure up to 50MPa

4、Test pressure 0~45MPa(The specific parameters shall be subject to the provisions of the contract between both parties)

5、Test efficiency 15~20只/hour(1pcs main machine,two water jets)

6、Test pressure control accuracy ≤0.06MPa

7、Water volume measurement accuracy ≤0.1g

8、Air supply pressure 0.6 MPa

9、Air consumption≈1.5 m3/min

10、VoltageAC220V

Description of Seamless Steel Cylinder Hydraulic Test Equipment:

The computer-controlled external measurement hydraulic testing machine is designed and manufactured according to the standard GB/T9251-1997 seamless steel cylinder hydraulic test method and DOT standard (reference), which can carry out external measurement hydraulic test on seamless steel cylinders of different specifications,includes oxygen cylinder,nitrogen cylinder,carbon dioxide cylinder,argon cylinder,etc, the following outstanding properties:

1.Use weighing method to read the weight of empty steel cylinders and the weight of steel cylinder which filled with water automatically,and calculate the volume

2.It adopts flowmeter control to add water automatically

3.The water jacket is compressed and sealed automatically, and the nozzle of test steel cylinder is sealed by self-sealing joint with internal expansion-high pressure style

4.Hydraulic test of seamless steel cylinder controlled by computer automatically

5.Collect and save water volume (deformation value), pressure and time data automatically

6.The time / water volume curve, time / pressure curve and water volume / pressure curve are dynamically displayed during the test

7.Calculate the residual deformation rate of the seamless steel cylinder and issue the test results (Excel format) automatically,

8.Save all test data,the test process and results can be queried according to the relevant cylinder data (such as test date, cylinder number, batch number, etc.) and re produced into a test report,etc

Structure and Configuration Of Seamless Steel Cylinder Hydraulic Test Equipment And Machine:

1、Seamless steel cylinder clamping turnover machine 2 sets 1 working station

2、Automatic filling device 1 set;water injection joint 1 set;irrigation can be settled

3、One set of wired hanging scale for cylinder weighing device, and the data can be collected by the computer directly

4、One set of hydraulic testing machine for external measurement of cylinders:

4.1 One set of test control system、Advantech IPC、LCD display、mouse、keyboard、Siemens PLC S7、communication module、communication cable system software

4.2 Pneumatic drive pump 1 set

4.3 Pressure sensor 1pcs

4.4 High pressure ball valve 1 set

4.5 Medium pressure ball valve 5 sets

4.6 Solenoid valve 5 pcs

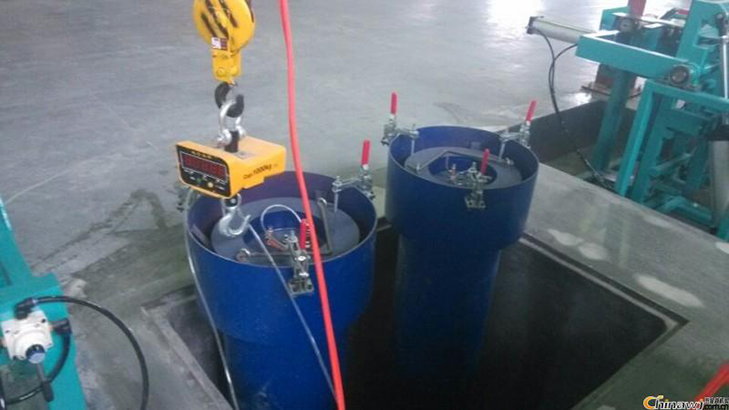

4.7 Steel water jacket 2 pcs

4.8 Water jacket cover 2 pcs

4.9 Main cabinet 1 set

4.10 Electronic balance 1 set JJ500

4.11 Hydraulic pipe valve system 1 set

4.12 Pneumatic control system 1 set

4.13 Electric control system 1 set

5、One set of gas cylinder suspension and hoisting device, including bracket, guide rail and chain electric hoist

6、Water pouring machine 1 set

Introduction of Hydraulic Test System of Seamless Steel Cylinder External Measurement Method:

The test device is developed in accordance with GB/T9251-1997 hydraulic test method for seamless steel cylinders, CGA C-1 hydraulic test method for compressed gas cylinders, and the relevant requirements of DOT standards. The control system of the test device is a computer industrial control hydraulic test system that can run under windows 98/2000/ XP operating system.

The test device is composed of control cabinet, water volume collection control cabinet, pressure test water jacket, gas cylinder hoisting equipment and weighing electronic scale (optional), as shown in the figure. The left side of the test device control cabinet is equipped with system control computer, and the right side is equipped with programmable controller, booster pump, high-pressure valve, various control valves and other data acquisition system control elements.

The front of the control cabinet includes operation display screen, operation computer keyboard and mouse, test pressure display instrument, and various operation button test devices. The control computer adopts windows 2000/2003 server operating system and MS SQL Server 2000 database management system, and the system software adopts CVI c++, VB and FN PLC language mixed programming. On the one hand, this setting can improve the stability of the system. On the other hand, users can install control software on other computers on the network node to perform all functions except hydrostatic test and standard bottle test module.

For example, the computer at the network node completes the weighing of gas cylinders, sets the parameters of hydrostatic test, prints the hydrostatic test report and views the hydrostatic test results. The hardware of the whole control system is composed of a control computer and an industrial computer. The upper and lower computers are distributed in two-level control mode. The control process and data acquisition are completed by the upper and lower computers through the RS-232 communication interface of RS-485 vehicle. The upper computer is used to set the initial parameters, real-time monitoring, dynamically process the test data, real-time test pressure, draw the water volume diagram and output the test report. The lower computer is composed of programmable controller (PLC), data acquisition, control module, pressure sensor, water level measurement sensor, RS-232 communication module, etc., which realizes the timing and quantitative control of high pressure pump, high pressure valve and solenoid valve during the test and the data collection during the test.

The designed higher working pressure of the test device is 40MPa, the actual test pressure control accuracy is not less than 10 psi, and the actual water level measurement accuracy is not less than 0.02cc. The test device has a high degree of operation automation when it works. After inputting the test cylinder number, it can be completed from weighing to completing the hydrostatic test by pressing the key a few times under normal circumstances. During the test, the time / pressure, time / water volume and pressure / water volume relationship curve during the test can be dynamically displayed in a graphical manner. The test device saves all the data of the test process, and the user can view all the test data and various test curves of the tested gas cylinders when necessary.

The hydraulic test system is composed of the upper operation part and the lower control part to complete the hydraulic test

This monitoring software can choose to control two water jackets for hydrostatic test. Before starting the monitoring software,check the power supply of the control cabinet and the connection of communication cables carefully.Check whether the communication cable of the weighing electronic scale is intact and whether the power supply of the weighing electronic scale is turn on.

The reading of the electronic scale should be stable and unchanged,when the hydrostatic test is not conducted.If the reading of the electronic scale cannot be stable, check the sealing condition of the waterway,check the pressure of the air supply source of the system (the booster pump air supply pressure <0.4mpa will not work normally) and the connectivity of the waterway carefully.

It is particularly necessary to check whether the weight of the water jacket has been sealed by the tested cylinder before the test, the water jacket and the high-pressure joint of the cylinder. There are valves in the water jacket to set which water jacket the monitoring system currently uses for hydrostatic test. There are water injection and exhaust valves in the water jacket and water valves for setting the pressure test water jacket, which are set well during use. If the sampling computer automatically controls the hydrostatic test, set the automatic pressure start / automatic pressure stop button to the automatic position, and set the hydrostatic test or test mode in the system parameter setting module. Generally, it is only necessary to set for a batch of test cylinders. During the pressure test, if two water jackets are used in turn during the pressure test, the selection valve of the used water jacket needs to be set correctly each time.