Fluoroplastic Magnetic Pump

TMF product summary

Design Features

Extreme design,the new style cancels the back cover,and the inner rotating parts adopt single point support,simple structure and long life.

Long life pair grinding material,silicon carbide grinding materials,shaft and shaft sleeve in operation will be subject to the pressure of the medium,between the formation of liquid film,greatly prolonging the service life.

New material,using a variety of new materials,you can replace different materials,custom-made high-temperature type,lye type,granular type.

Use,chlor-alkali,fluorine,benzene,alcohol,foils,pickling,pesticides,seawater desalination,medicine and other industries strong acid strong base medium transport.

Installation height calculation

In selecting the pump in our company,the installation height should be considered.

The vertical distance between the suction level and the pump shaft should be less than the installation height specified by the pump.The following formula is used to calculate:

Hsz ≤Ha-Hv-Δ Hs-(NPSH)r

Hsz-Fixed installation height (m)

Ha-Atmospheric pressure head on site

Hv-Vaporization pressure head of liquid temperature (m)

NPSH-cavitation allowance specified on the performance parameter table(m)

Pump shaft power

Pump power refers to the input power of the pump,is N.

The output power is the effective power transferred by the pump to the liquid as it passes through the pump,is NE.

Ne= p X g X Q X H

p=Liquid density(m3/kg)

g=Gravity acceleration(m/s)

Q=Flow(m3/h)

H=Head(m)

Input power and output power are not equal,because there is a loss of power in the pump,the size of the loss is commonly used to measure the efficiency of the pump.Efficiency is expressed by Ƞ.The efficiency of pump is the ratio of output power to input power.

Ƞ=Ne/N

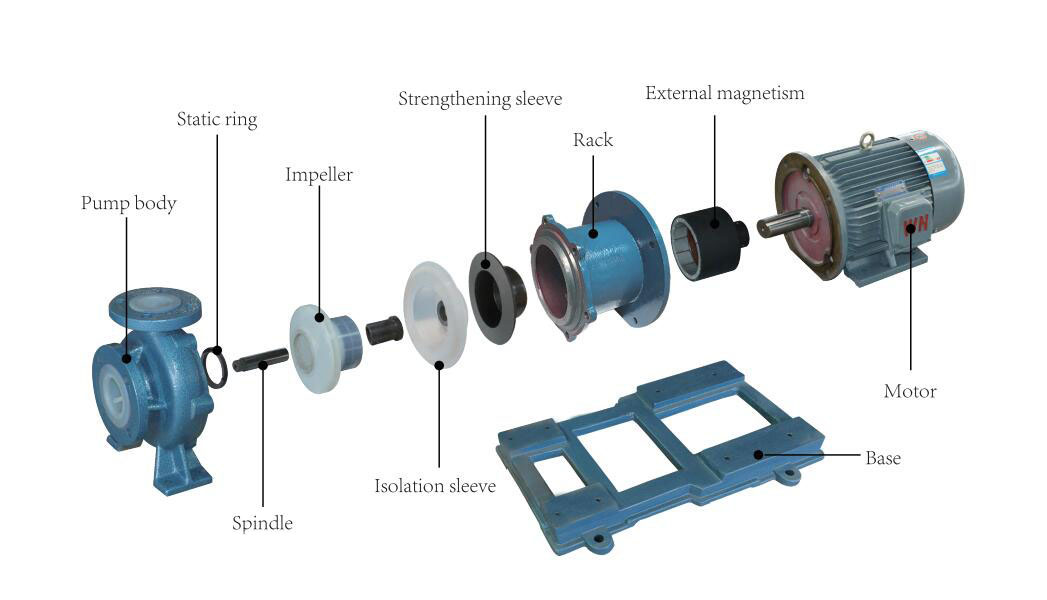

Part disassembly drawing:

Technical Characteristics

Internal magnetic external steel:

Magnetic pump in normal operating conditions,there is no phenomenon of aging demagnetization with the passage of time.However,demagnetization will occur when the pump is overloaded,blocked,slid or operating temperature is higher than the allowable temperature of magnetic steel.Therefore,the magnetic pump must operate under normal operating conditions.

Strengthening sleeve:

High resistivity and high strength non-metallic materials are used to make the strengthening sleeve,which can effectively reduce the magnetic eddy current.

The pressure limit of the strengthened sleeve is 1.0 Mpa

Impeller and mouth ring:

The impeller is made by integral moulding,and the steel insert is wrapped in fluoroplastic to ensure the strength of the impeller.The oral ring is generally made of filled polytetrafluoroethylene or silicon carbide material,super wear resistant and corrosion resistant.

Pump shell:

Made with HT200 lining F46,it can withstand part of the pipe gravity.

Adopt HT200 integral casting molding,the upper and lower all adopt the gantry milling machine to flatten,maximize to achieve the level and stability of the pump.

Sliding bearing:

Tetrafluorine filled graphite,carbon fiber material,wear resistant,corrosion resistance.

Matters attention

1.Fluorine-lined centrifugal pump transport media is not allowed to contain ferromagnetic impurities and hard impurities,if there are ferromagnetic particles,then need to add magnetic filters.

2.The fluorine-lined centrifugal pump is not allowed to operate at a rated flow rate of less than 30%.

3.For the delivery of density greater than 1200kg/m liquid,we need to inform our sales department,motor power needs to be appropriately increased.

4.The maximum working prssuure of mechanical seal is 1.0 Mpa,beyond which a mechanical seal thrust ring is required.

5.Prevent static electricity destruction:when conveying liquid with low conductivity,such as ultra-pure water or fluorine-containing inert liquid,static electricity will occur in pump,which will cause discharge and pump damage.Anti-static production,elicitation or other measures should be taken.(please consult the technical department of our company)

6.Special medium selection of special grinding parts,such as hydrofluoric acid selection pressureless sintering silicon carbide,nitric acid choice ceremic or silicon carbide.

Installation instructions

1.Build the concrete foundation according tothe size,at the same time bury the anchor bolt.

2.The equipment of pump group should be checked carefully before installation,all parts should be intact and there is no sundries in pump cavity.

3.Put the pump unit on the basis,put the pair of wedge cushion between the bottom plate and the foundation,and find the level by adjusting the wedge cushion.

4.The inlet and outlet lines of the pump should be supported separately by support.

5.After installation,the coupling is rotated with bare hands to check whether there are any phenomena such as rubbing,running and so on.The rotation is easy and easy.

6.In order to prevent sundries from entering the pump,the Teng long pump valve suggests that a filter should be set at the inlet,and the filter area should be 2-3 times large than the cross section area of the pipeline.

7.The pump with high lift should be installed with reverse stop valve on the outlet line to prevent damage caused by sudden shutdown.

8.The installation height of the pump must be in accordance with the cavitation allowance of the pump and the pipeline loss and the temperature of the medium must be considered.

Start operation

1.Before opening the equipment,fill the pump chamber with the liquid to be transported,close the outlet valve,and connect to the power supply.

2.Turn on the power supply and check if the steering of the pump is correct in the direction of the sign

3.Pump unit trial operation 5-10 minutes,if there is no abnormal phenomenon can be put into operation.

4.When stopping,the outlet valve should be closed first,and then the power supply should be cut off.

Equipment disassembly

1.Wash the pump body with clear water first when dissembling until the corrosive medium inside the pump shell is completely clean

2.When replacing pump machine fittings,may not use sharp object,hard object to hit the pump parts,the removed parts should be light,sealing face facing up.

Maintenance

1.Periodic inspection of pumps and motors,replacement of vulnerable parts

2.When the long-term stop is not needed,clean the flow channel inside the pump and cut off the power supply,and cover the dust cover

3.Reverse and idling is forbidden to turn on according to instructions.

After-sale service

Provision of spare parts:

Tenglong is able to quickly and reliably supply vulnerable parts and spare parts needed in the production phase to ensure that production does not stagnate.

Equipment maintenance:

Tenglong will help customer to maintain equipment,timely detection of weak links to reduce or even avoid repair costs.

Technial support: Tenglong service,dedicated and meticulous.

We will provide consultation for customers,elite after-sales team,expert technical guidance,throughout the product design,selection,sales,use of the entire prcess.

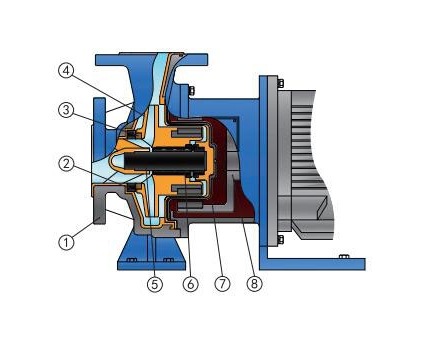

Materials and structures

Impeller diameter less than 250mm

1 Pump sheel HT200/F46

2 Static ring SIC

3 Moving ring Filled tetrafluoride

4 Impeller F46/NdFeB

5 Spindle SIC

6 Shaft sleeve SIC

7 Isolation sleeve F46/PEEK

8 External magnetism HT200/NdFeB

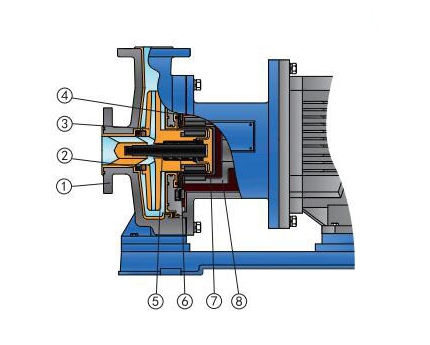

Impeller diameter more than 250mm

1 Pump sheel HT200/F46

2 Static ring SIC

3 Impeller F46/NdFeB

4 Back cover HT200/F46

5 Spindle SIC

6 Shaft sleeve SIC

7 Isolation sleeve F46/PEEK

8 External magnetism HT200/NdFeB

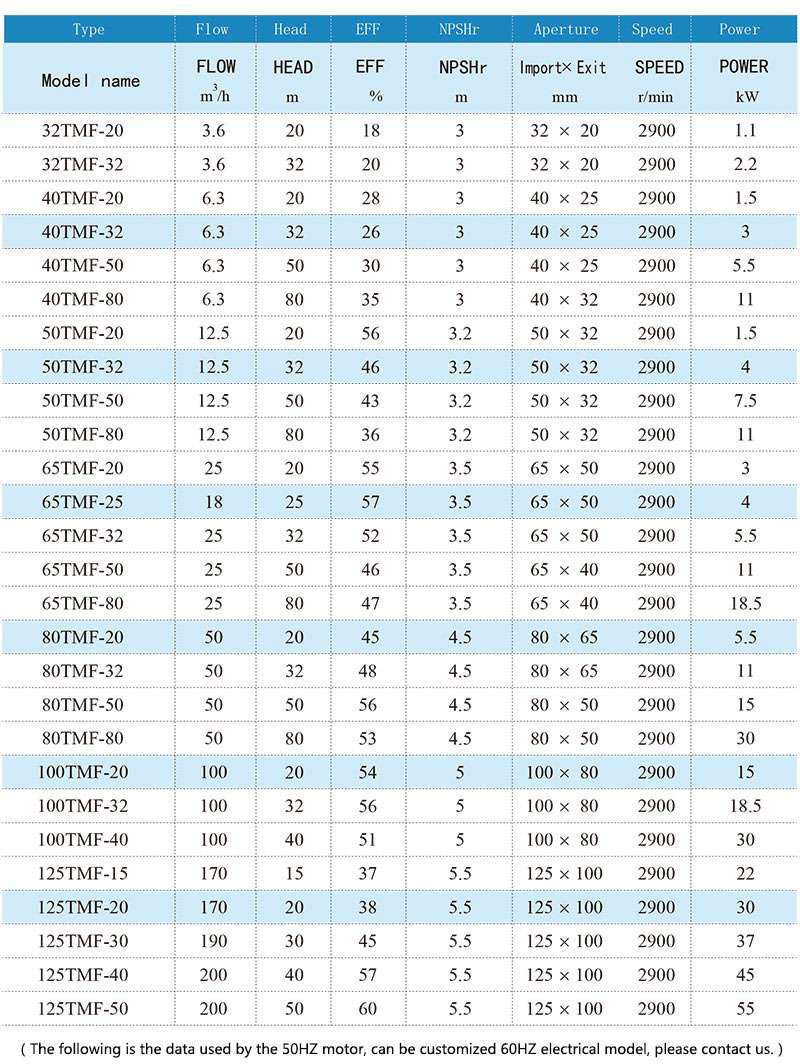

Performance Data

TMF magnetic pump can be used according to the requirements,customized products:

1.High temperaturue type-G,maximum temperature 180c

2.Lye type-J,Transport alkaline liquid

3.Granular type-K,Transport of 10% particulate matter.

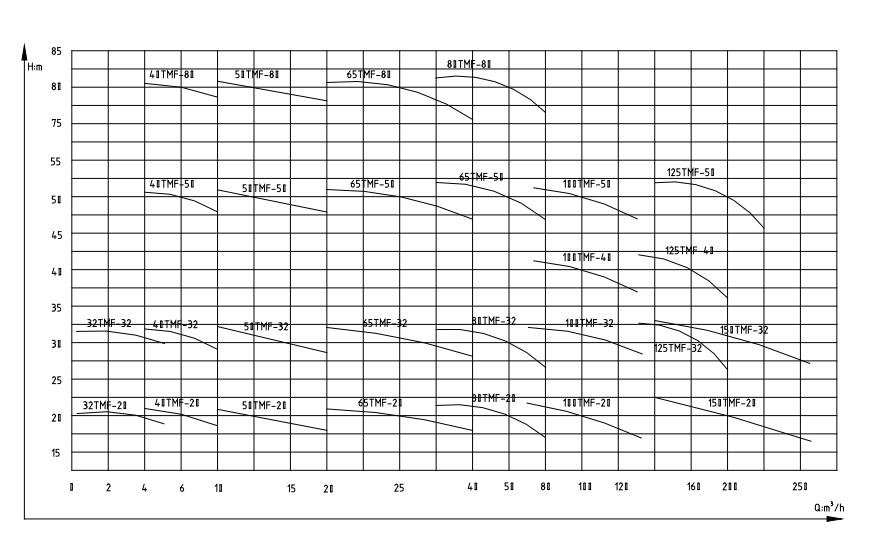

Performance Curve

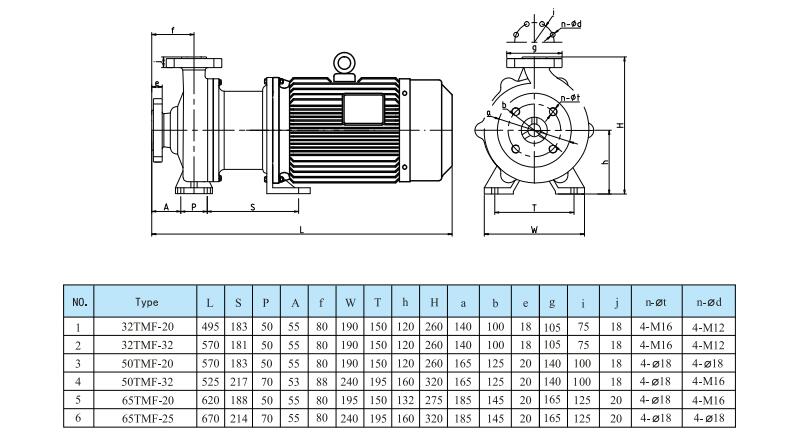

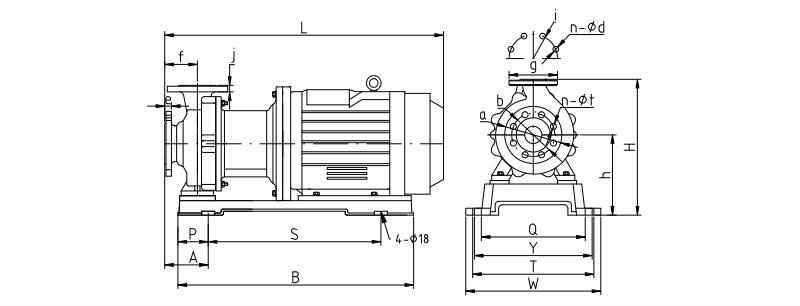

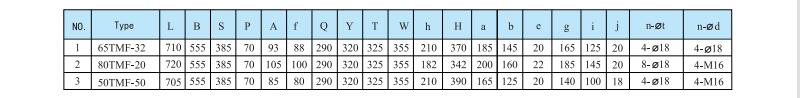

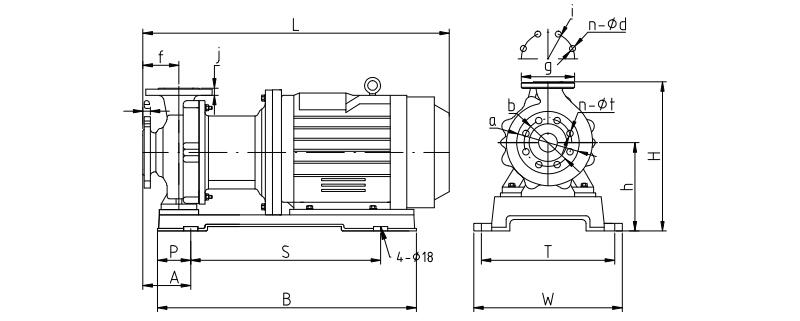

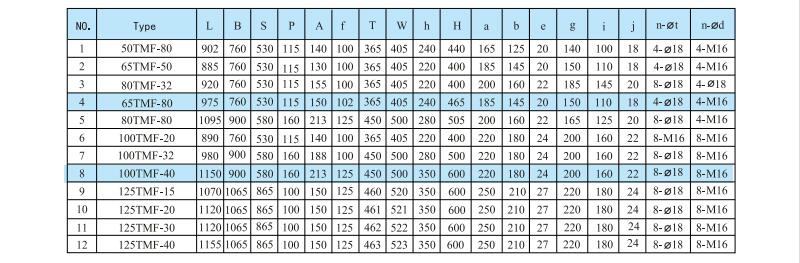

Mounting Size