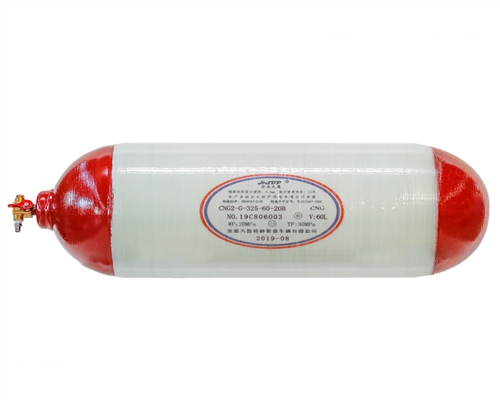

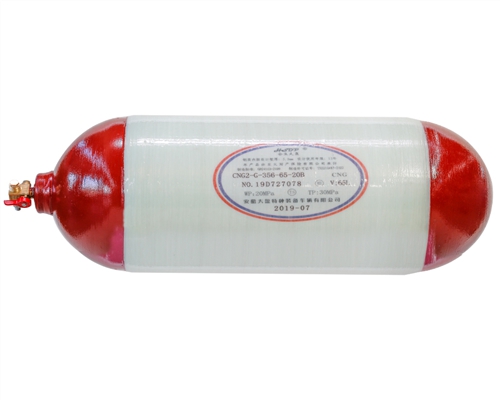

ECE R110 Standard Type II Vehicle CNG Cylinder

The ECE R110 certification is a technical standard for the approval of Compressed Natural Gas (CNG) fuel system components installed on vehicles. It is an internationally recognized certification developed by the United Nations Economic Commission for Europe (UNECE) and is mandatory for CNG cylinders used in most countries.

The ECE R110 certification sets the requirements for CNG cylinders, including material properties, design and construction, type approval tests.

CNG cylinder full name is compressed natural gas cylinder,it is a high-pressure container used to store compressed natural gas. This high-pressure container containing flammable and explosive gas is a pressure container with explosive danger. The gas storage pressure of vehicle gas cylinder is 20MPa.In the Chinese market, it mainly focuses on the production and sales of CNG-2 type cylinder.

ECE R110 Standard Type II Vehicle CNG Cylinder

The ECE R110 certificate is a regulation issued by the United Nations Economic Commission for Europe (UNECE) that sets the standards for the approval of Compressed Natural Gas (CNG) cylinders for use in vehicles.

Specifically, ECE R110 provides requirements for the construction, testing, and installation of CNG cylinders and their valves, as well as requirements for their use, maintenance, and periodic inspection. The goal of ECE R110 is to ensure the safety of CNG cylinders and their associated components, including their installation, maintenance, and use in vehicles.

In order to obtain the ECE R110 certificate, a CNG cylinder must undergo rigorous testing and meet the requirements outlined in the regulation. Once approved, the cylinder can be used in vehicles that comply with the European Union regulations for the use of CNG as a vehicle fuel.

CNG cylinder full name is compressed natural gas cylinder,it is a high-pressure container used to store compressed natural gas. This high-pressure container containing flammable and explosive gas is a pressure container with explosive danger. The gas storage pressure of vehicle gas cylinder is 20MPa.In the Chinese market, it mainly focuses on the production and sales of CNG-2 type cylinder.

The ECE R110 certification is a technical standard for the approval of Compressed Natural Gas (CNG) fuel system components installed on vehicles. It is an internationally recognized certification developed by the United Nations Economic Commission for Europe (UNECE) and is mandatory for CNG cylinders used in most countries.

The ECE R110 certification sets the requirements for CNG cylinders, including material properties, design and construction, type approval tests.

CNG is the English abbreviation of compressed natural gas. Compressed natural gas generally refers to the gaseous natural gas (methane as the main component) that can be used as fuel for vehicle engine after multistage pressurization to about 20MPa.

Classification:

CNG cylinders are divided into four categories

The first type is steel or aluminum alloy metal bottle (CNG-1);

The second type is steel or aluminum lined composite gas cylinder (CNG-2) with barrel reinforced by "hoop winding" resin impregnated long fiber;

The third type is steel or aluminum lined composite gas cylinder (CNG-3) reinforced with "integral winding" resin impregnated long fiber;

The fourth type is the composite gas cylinder (CNG-4) reinforced by plastic lining and "integral winding" resin impregnated long fiber.

These cylinders have their own advantages and disadvantages, and can be selected and used according to different models

At present, steel cylinders are mainly used in China, and their performance must meet the requirements of GB 17258 compressed natural gas cylinders for automobiles. The cylinder body material is generally high-quality chromium molybdenum steel

A complete compressed natural gas cylinder for automobile shall be equipped with cap,valve and safety pressure relief device. The cap can protect the valve, and the safety pressure relief device on the bottle valve shall be a combination of bursting disc and fusible plug

Precautions for use:

1. The use and installation of compressed natural gas cylinders for automobiles shall comply with the provisions of relevant standards. They shall be refitted and repaired by a regular Refitting Factory with CNG automobile refitting qualification uniformly issued by authority institute, including the installation and disassembly of cylinders. It is strictly prohibited for unqualified units to refit, repair, disassemble and inspect gas cylinders. It is not allowed to repair, weld and repair gas cylinders. The original manufacturing mark and nameplate of gas cylinders shall be complete, the contents shall be complete and the steel seal shall be clear; Visually check that there is no permanent deformation on the surface of the cylinder, and the cylinder valve shall be intact

2.Before and after filling, the safety status of gas cylinders and their accessories shall be inspected; The filled gas must be dehydrated, desulfurized and de oiled overpressure filling is strictly prohibited, the natural gas in the bottle shall not be exhausted, and the residual pressure above 0.1MPa shall be reserved; The working pressure of the gas cylinder is the limited filling pressure at the reference temperature (20 ℃), the filling pressure of the gas cylinder shall be adjusted according to the actual temperature during inflation, and the temperature compensation value shall be in accordance with the regulations of the inflation station. The new gas cylinder shall be vacuumized before the first inflation

3.During the use of the gas cylinder, if it is found that the gas filling is inconsistent with the usual mileage, or the pressure in the gas cylinder decreases significantly after a period of exercise, it is necessary to be vigilant and check whether there is air leakage in time. In case of serious corrosion, damage or doubt on its safety, it shall be inspected in time

4.The composite material layer of cylinder shall not be scratched, bumped or corroded by acid. The isolation rubber pad shall be used between the gas cylinder and the fastening belt and the installation support and shall be fastened well. The worn and deformed rubber pad shall be replaced in time. For wound gas cylinders, pay attention to the integrity of the winding layer, keep the surface clean and prevent chemical corrosion; Do not place hard objects in the trunk to avoid bumping and knocking the surface of the cylinder. Do not put heavy objects on the gas system pipeline

5.It is forbidden to contact with grease, chemicals, hardware and other substances, scratch, bump, corrosion and extrusion. The gas cylinder shall not be close to the heat source and exposed to the sun. The distance from the open fire shall not be less than 10m, and the gas cylinder shall not be impacted

6.The trunk where the gas cylinder is located shall use as few or no electrical components as possible. If it must be used, it shall also have explosion-proof performance and be installed away from the gas cylinder as far as possible

7.The interfaces of gas cylinder, inflation valve and pressure reducer that are easy to leak shall be inspected frequently

8.It is strictly prohibited to bake with fire when the cylinder valve is frozen. It is forbidden to heat the gas cylinder with a heat source exceeding 40 ℃; It is forbidden to conduct electric welding and arc striking on the gas cylinder

9.The isolation rubber pad shall be used between the gas cylinder, the fastening belt and the mounting bracket and shall be fastened well. The worn and deformed rubber pad shall be replaced in time

10.In case of failure of safety accessories during the use of gas cylinders: cylinder valve, fusible alloy plug, gas leakage cylinder valve switch failure, etc., first move the vehicle to a safe place, set a warning line, and send it to the cylinder inspection unit or natural gas vehicle repair shop for treatment after the compressed natural gas is released. It is forbidden to repair or replace accessories by yourself

11.Inspection shall be carried out at any time in case of the following accidents:

A.accidents, gas cylinders or vehicles on fire, impact, overheating or damage by other means

B.damaged or contaminated by chemicals

C.cylinder overpressure or damage by hard objects and vehicles

D.other abnormal conditions, including natural gas pungent smell (confirmed as non pipeline leakage), unexplained gas pressure drop, abnormal sound and signs of loose installation

E.cylinders stored or out of service for more than one inspection cycle shall be inspected before use

F.other abnormal conditions occur

Specifically, ECE R110 provides requirements for the construction, testing, and installation of CNG cylinders and their valves, as well as requirements for their use, maintenance, and periodic inspection. The goal of ECE R110 is to ensure the safety of CNG cylinders and their associated components, including their installation, maintenance, and use in vehicles.

In order to obtain the ECE R110 certificate, a CNG cylinder must undergo rigorous testing and meet the requirements outlined in the regulation. Once approved, the cylinder can be used in vehicles that comply with the European Union regulations for the use of CNG as a vehicle fuel.

Type CNG -356-60,Water Capacity 60L, dia 356mm Working Pressure 200bar Hydraulic Test Pressure 300bar

Type CNG -356-75,Water Capacity 75L, dia 356mm Working Pressure 200bar Hydraulic Test Pressure 300bar

Type CNG -356-100,Water Capacity 100L, dia 356mm Working Pressure 200bar Hydraulic Test Pressure 300bar