Steel Shots for LPG Cylinder Shot Blasting Machine

08 April 2024

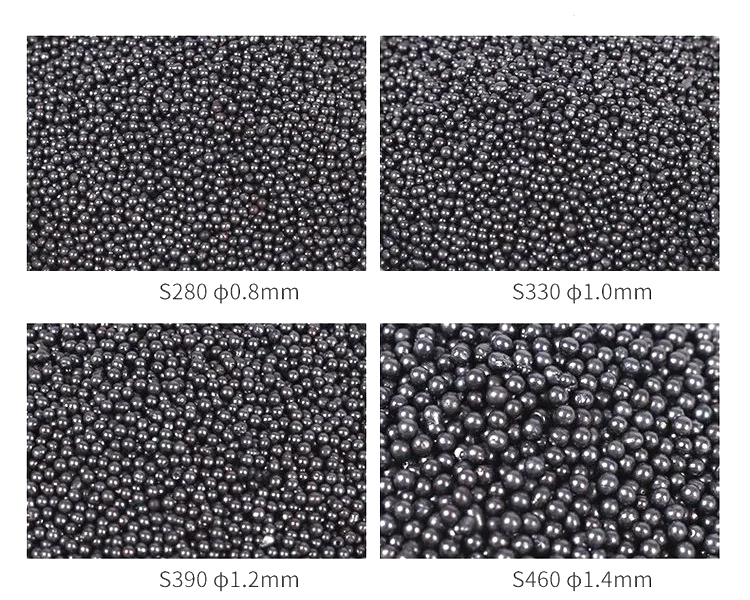

Steel shot is a type of spherical particle made from special materials through heating treatment. Firstly, high-quality steel blocks, wire rods, and steel scraps are melted together, then the molten steel is thrown into water at high speed using a centrifugal machine to cool the surface temperature rapidly, forming spherical shapes. This is a quenching process,The quenched pellets are dried and reheated in the furnace for tempering to achieve the desired hardness. After tempering, the steel shot is sorted into different grades according to SAE standards using mechanical sieves for use in shot blasting equipment. The heat treatment process imparts good elasticity to the steel shot, and steel shots with different particle sizes and hardness are suitable for different processes.

In order to select the type of steel shot, factors to consider include the machine model used, the type and size of the material being processed, and the type of stains to be cleaned. Here are some considerations when choosing the appropriate steel shot:

Machine model selection: The specifications and models of the machine also have significant requirements for selecting steel shot. Different machine models and specifications require different types of steel shot and pressure. Therefore, when choosing steel shot, it is necessary to first understand the specifications and requirements of your machine parameters.

Understanding of the material being processed: Learn to recognize the material being processed and understand its surface condition. If the surface contamination of the material being processed is light, choose larger diameter steel shot for polishing; if the surface contamination is severe, finer steel shot is needed for polishing.

In order to select the type of steel shot, factors to consider include the machine model used, the type and size of the material being processed, and the type of stains to be cleaned. Here are some considerations when choosing the appropriate steel shot:

Machine model selection: The specifications and models of the machine also have significant requirements for selecting steel shot. Different machine models and specifications require different types of steel shot and pressure. Therefore, when choosing steel shot, it is necessary to first understand the specifications and requirements of your machine parameters.

Understanding of the material being processed: Learn to recognize the material being processed and understand its surface condition. If the surface contamination of the material being processed is light, choose larger diameter steel shot for polishing; if the surface contamination is severe, finer steel shot is needed for polishing.

Selecting appropriate application: Steel shot has a wide range of uses, and different applications correspond to different material characteristics. Therefore, when choosing steel shot, it is necessary to fully consider its purpose and the scene it will be used in, and select the appropriate type to achieve the best polishing or surface cleaning effect.